Yog tiastooj liab phajyog siv rau lub sij hawm ntev, qhov saum npoo ntawm lub phaj tooj dag yuav ua ntxhib, thiab nws yuav ua rau lub phaj tooj dag oxidize, uas yuav cuam tshuam rau kev siv txuas ntxiv ntawm cov phaj tooj dag.Polishing lub phaj tooj dag tuaj yeem txhim kho qhov smoothness ntawm lub phaj, thiab nws kuj muaj qee yam kev ua haujlwm los tiv thaiv oxidation, yog li dab tsi yog txheej txheem polishing ntawm cov phaj tooj dag?Dab tsi yuav tsum tau ceev faj thaum polishing?

1. Brass phaj polishing txheej txheem

1. Thaum lub sijhawm ua haujlwm polishing, npaj cov tooj liab polishing ua haujlwm zoo raws li cov lus qhia, thiab sim ua haujlwm hauv qhov chaw cua ntawm chav tsev kub, kom tsis txhob cuam tshuam rau kev siv cov tshuaj polishing.

2. Tom qab npaj cov tooj liab polishing tov, tsau lub phaj tooj dag hauv cov tshuaj polishing, tshem tawm cov phaj tooj liab tom qab 2-3 feeb, thiab tam sim ntawd muab tso rau hauv dej huv rau kev ntxuav, thiab ntxuav cov kua seem.

tshuaj rau ntawm lub workpiece kom tsis txhob cuam tshuam rau kev siv tom ntej.

3. Tom qab lub phaj tooj dag yog polished thiab ntxuav, nws tuaj yeem nkag mus rau cov txheej txheem tom ntej kom txau thiab passivate lub phaj tooj dag.Txhawm rau tiv thaiv lub phaj tooj liab los ntawm kev hloov xim tom qab polishing, nws yog ib qho tsim nyog yuav tsum tau ua kom cua qhuav thiab passivate lub phaj tooj dag hauv lub sijhawm.

4. Thaum lub sij hawm polishing txheej txheem, yog tias nws pom tias lub ntsej muag gloss ntawm lub phaj tooj dag tsis tau raws li qhov yuav tsum tau ua, cov khoom tsim nyog tuaj yeem muab ntxiv rau cov tshuaj polishing.Qhov ntau npaum ntawm cov tshuaj ntxiv yog 1% -2% ntawm thawj polishing tov.Qhov sib ntxiv yog ua raws li ib qho me me Ntau lub hauv paus ntsiab lus.Yog tias nws tseem tsis tau raws li qhov yuav tsum tau ua tom qab ntxiv cov khoom ntxiv, nws yuav tsum tau hloov nrog tus neeg sawv cev tshiab polishing.

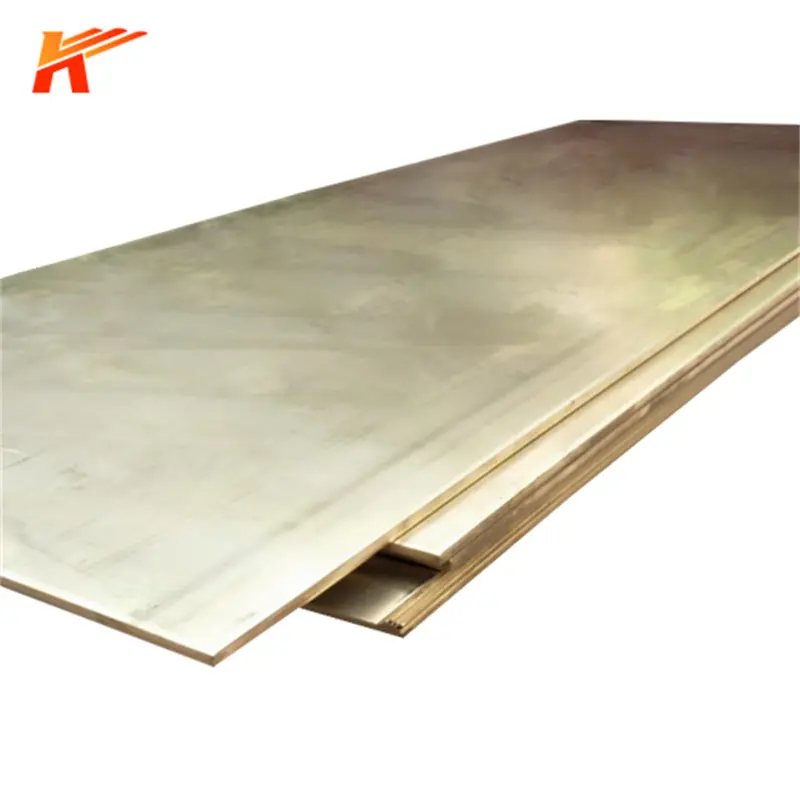

tooj liab phaj

2. Kev ceev faj rau cov phaj tooj dag polishing

1. Sim siv cov yas pp tso tsheb hlau luam rau lub tank ua haujlwm uas muaj cov kua polishing, thiab tsis txhob siv hlau, ceramic thiab lwm lub tank ua haujlwm.

2. Thaum lub sij hawm polishing txheej txheem, xyuam xim rau co los yog tig lub workpiece los tiv thaiv lub overlapping nto ntawm lub workpiece los ntawm kev sib cuag nrog cov dej ua hauj lwm zoo.

3. Thaum polishing, lub workpiece tsis tuaj yeem polished ntau dhau ntawm ib zaug, thiab yuav tsum muaj qhov sib txawv ntawm cov khoom ua haujlwm kom tsis txhob muaj cov nyhuv polishing tsis zoo.

4. Tom qab polishing tiav lawm, cov tshuaj kua uas seem yuav tsum tau muab ntxuav kom tsis txhob muaj kev cuam tshuam rau nws txoj kev siv thaum lub sij hawm tom ntej.

5. Tom qab polishing, muab lub phaj tooj dag tso rau hauv qhov chaw txias thiab qhov cua kom khaws cia.

6. Cov kua polishing yog corrosive rau ib qho twg.Thaum lub sijhawm ua haujlwm, yuav tsum tau saib xyuas kom tiv thaiv cov kua los ntawm kev sib cuag nrog tib neeg daim tawv nqaij.Ua tib zoo saib xyuas kom tsis txhob ua kua los ntawm kev txaws.

7. Tom qab tshuaj polishing, nws yog ib qho tsim nyog yuav tsum tau ua raws li kev tiv thaiv kev kho mob raws sij hawm.Soak hauv tooj liab tiv thaiv tus neeg sawv cev rau 30 vib nas this, uas tuaj yeem txhim kho cov oxidation tsis kam ntawm cov phaj tooj dag.

Post lub sij hawm: Mar-03-2023