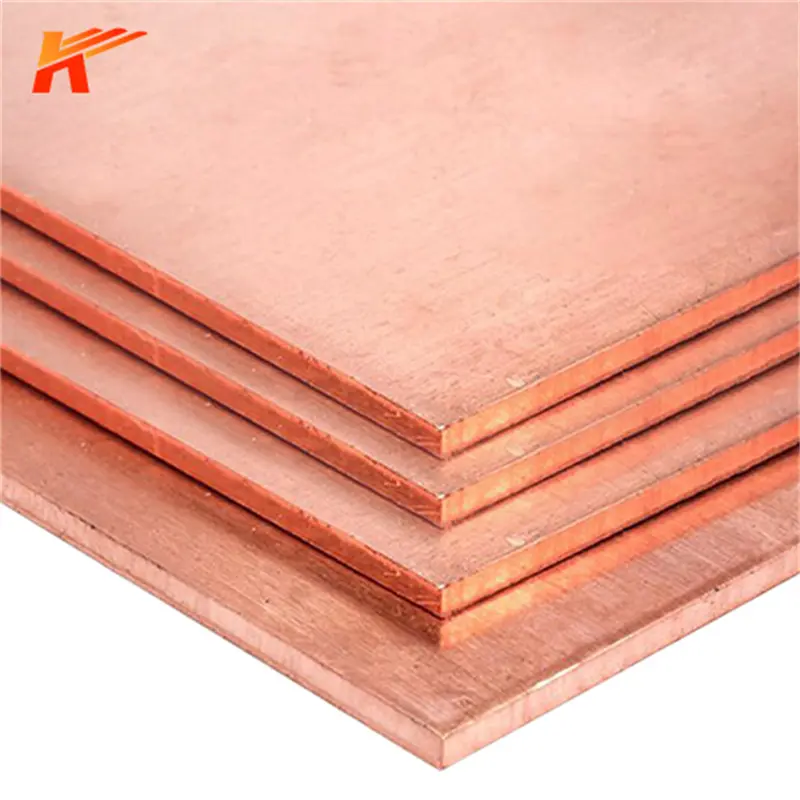

Daim ntawv tooj liab yog ib yam tseem ceeb ntawm cov khoom siv tooj liab.Nws muaj lub cev muaj zog, zoo heev conductivity, hloov tshav kub, zoo heev corrosion kuj, electroplating txheej txheem, fibrous vuam, thiab zoo nkauj thiab zoo nkauj hlau zoo nkauj thiab zoo heev zoo Cov tsim thiab ua cov yam ntxwv ntawm molding ntau lawm, yog li nws tau lug siv nyob rau hauv lub zog engineering. kev lag luam nrog ntau yam sib txawv engineering, khoom siv hauv tsev riam phom thiab khoom siv.

yog ib yam tseem ceeb ntawm cov khoom siv tooj liab.Nws muaj lub cev muaj zog, zoo heev conductivity, hloov tshav kub, zoo heev corrosion kuj, electroplating txheej txheem, fibrous vuam, thiab zoo nkauj thiab zoo nkauj hlau zoo nkauj thiab zoo heev zoo Cov tsim thiab ua cov yam ntxwv ntawm molding ntau lawm, yog li nws tau lug siv nyob rau hauv lub zog engineering. kev lag luam nrog ntau yam sib txawv engineering, khoom siv hauv tsev riam phom thiab khoom siv.

Ntawm no yog yuav ua li cas lub phaj tooj liab ua:

1. Txias dov-sawing txoj kev

Cov txheej txheem tsim khoom yog: casting thiab cua sov-kub taver- (milling nto-qhib-txias dov-quenching-) Picky thiab passivation-txias dov-sawing Lub tsev kawm ntawv yog ncaj-ntim-ntim-ntim rau hauv warehouse.Cov yam ntxwv yog tias qhov kev ua tau zoo ntawm cov phaj tooj liab tuaj yeem tau txais txiaj ntsig zoo, tab sis muaj cov npoo plaub hau thiab ua yeeb yam, cov npoo tsis yog arc, txheej txheej saum npoo tsis du, tag nrho qhov dav yog loj, thiab cov kev cai siab-precision. tsis tau ntsib.Tus nqi khoom yog siab dua.

2. Txias dov-Lashen txoj kev

Cov txheej txheem ntau lawm yog: casting thiab cua sov-kub taver-milling nto-txias dov-txiav strips-quenching thiab passivation-La Shou-cam khwb cia thiab dov tsev kawm ntawv ncaj-ntim-packaged- Nkag mus rau hauv warehouse.Tus cwj pwm yog tias txhua yam ntawm cov qauv zoo tuaj yeem tau txais kev tswj xyuas zoo thiab kev tsim khoom qis, tab sis cov phaj tooj liab txiav cov npoo thiab qhov siab ntev tsis tuaj yeem tswj tau.

3. Txias dov txoj kev ntawm txhuas profile

Cov txheej txheem ntau lawm yog: hlau pwm liab ingot-kub (sov) dov-pickled passivation-dov aluminium profile-quenching thiab passivation-refined aluminium profile-cam khwb cia dov tsev kawm ntawv ncaj nraim txhua qhov chaw ruaj khov River- ntim- nkag mus rau hauv warehouse.Cov yam ntxwv yog tias qhov kev ua tau zoo ntawm cov phaj tooj liab tuaj yeem tau txais kev ua haujlwm zoo.

4. Squeezing molding-Lashen txoj kev

Cov txheej txheem ntau lawm yog: casting thiab cua sov-squeezing molding-Lashen-quenching-pickling passivation-La Sulin-casting thiab dov tsev kawm ntawv ncaj qha- ntim- ntim.Cov txheej txheem txheej txheem no ntxiv nrog quenching thiab pickling cov txheej txheem kom paub meej tias cov phaj tooj liab yog 180 ° dabtsi yog khoov cov yam ntxwv, thiab cov qauv zoo yog tswj.Cov txheej txheem yog qhov yooj yim, kev ua haujlwm siab, muaj peev xwm ntau lawm, tab sis cov nqi khoom kuj yog siab heev.

5. Quoting (los yog theem) Rolling steel-txias dov-Lashen txoj kev

Kev tsim khoom thiab kev tsim khoom ntawm cov chaw tsim khoom siv tooj liab yog: sab sauv (los yog theem) dov steel-txias dov-quenching-pickling passivation-Lashen-Laoshen-Casting thiab dov tsev kawm ntawv ncaj-ntim-ntim tsev qiv ntawv.Cov yam ntxwv yog tias cov txheej txheem yog qhov yooj yim thiab cov nqi khoom qis.Txawm li cas los xij, kev ua haujlwm tsis zoo tsis zoo dua li lwm txoj hauv kev.Specifications yog txwv, tsis tshua muaj efficiency, thiab me me peev xwm ntau lawm.

Post lub sij hawm: Oct-21-2022